We design and deliver mixers for you within 7 days as standard

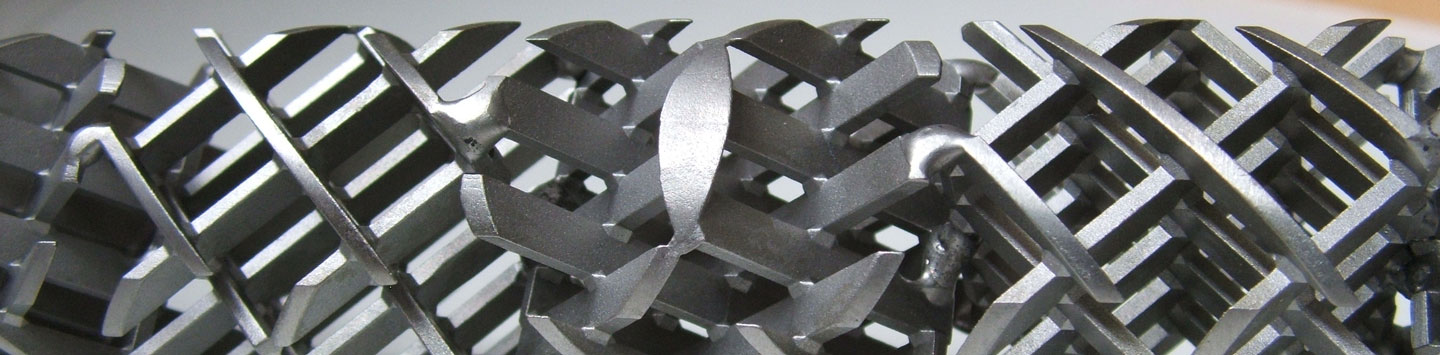

We take your requirements into account when designing mixers for you. If they are highly specific to the needs of your operation, we will custom build mixers for you and perform laboratory and semi-operational tests. We constantly have in stock a range of standard mixers with diameters from DN15 to DN150, and we can supply them to you within 7 days.

We manufacture the mixers in the European Union and you can rely on their quality.

We always take the following into account when designing static mixers:

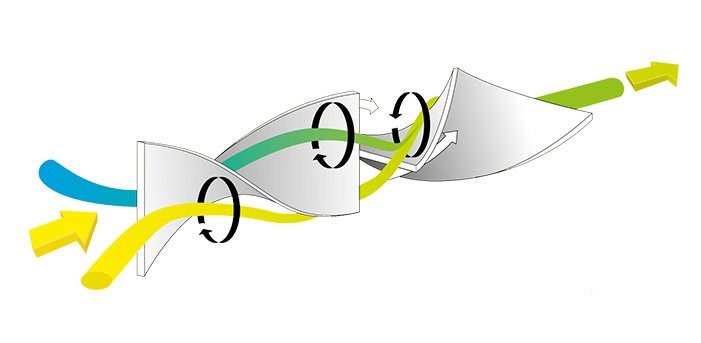

- Required level of homogenisation

- Chemical resilience of used materials in terms of mixed components

- Minimal pressure loss

- Minimal area taken up

We also offer:

- Versions with or without injector

- Broad possibilities for process connection, including:

- DIN, ASME, ANSI flanges

- BSP, NPT threads

- Clamp, Victaulik and other systems

- Wide range of materials and their surface finishes, including:

- Steel with outer RAL surface finish

- Stainless steel AISI 304 (1.4301), AISI 316 (1.4404), Duplex (1.4462)

- Steel with polymer coatings PTFE, PFA, ETFE, …

- PP, PVC, PVDF

- Static mixers for high pressures and for environments with explosion danger

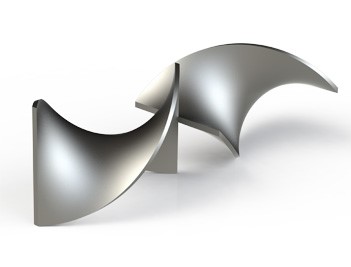

Excellent homogenisation without moving components

Maintenance-free and fault-free operation

Low operating costs

We always take the following into account when designing static mixers:

- Required level of homogenisation

- Chemical resilience of used materials in terms of mixed components

- Minimal pressure loss

- Minimal area taken up

Write to us