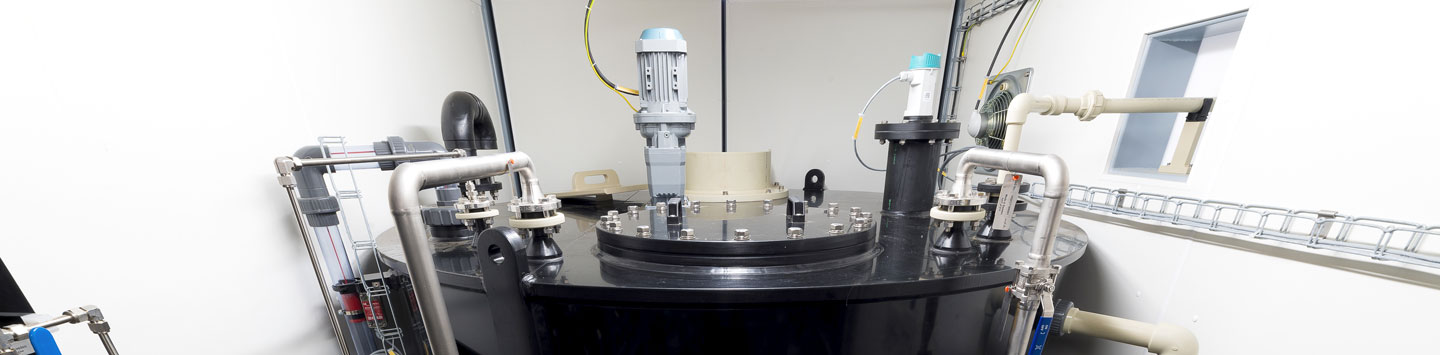

Industry vertical stirrers

Choose a reliable and cost-effective solution for stirring and homogenisation in tanks. Our electrical vertical stirrers are mechanically robust and suitable for use in various industrial processes.

Based on your requirements we will make a professional selection of the optimal motor output, length, rotation speeds, and material for the shaft and design of the rotor. We also test the proposed solution under laboratory and semi-operational conditions.

We keep a wide range of standard stirrers in stock for you and are capable of delivering them within 10 days. Our vertical stirrers are made in the EU and you can rely on their quality.

Enquire about vertical stirrers

We offer:

- Stirrers for various shapes and sizes of tank

- Stirrers for pressurised tanks

- Wide range of materials and their surface finishes, including:

- Steel with outer RAL surface finish

- Stainless steel AISI 304 (1.4301), AISI 316 (1.4404), Duplex (1.4462)

- PP, PVC, PVDF

- Customer solutions for stirring using vertical stirrers, custom manufacture of stirrers

- Laboratory and semi-operational tests of stirrers

- Stirrers for environment with explosion danger