We design suitable technologies for your operation

We supply membrane technologies for filtering liquids from renowned manufacturers for any branch of industry and for municipal processes. Out of the inexhaustible number of technologies we select for you the most suitable means of separation and the type of corresponding membrane equipment, and we verify the selected solution through laboratory or semi-operational tests.

Wide selection of membranes

We have membranes for you with differing porosity and MWCO for all processes and a wide range of dimensions of membrane modules. As a result, it is possible to use our modules quickly and without construction alterations directly in your filtration systems.

We also supply certified membranes and modules for the food industry and pharmacy, membranes with FDA, TSE, BSE certificates.

In our range you will find:

- Spiral wound membrane modules

- Tubular membrane modules

- Membrane modules made of hollow fibres

- Membrane formats M35N, M37N, M39N and rolls

- Membrane modules for MBR

Non-standard membrane solutions

We adapt membranes of various types and shapes to your specific requirements. In cooperation with our partners we develop membrane elements tailored to your equipment and processes, and we can supply them under your brand.

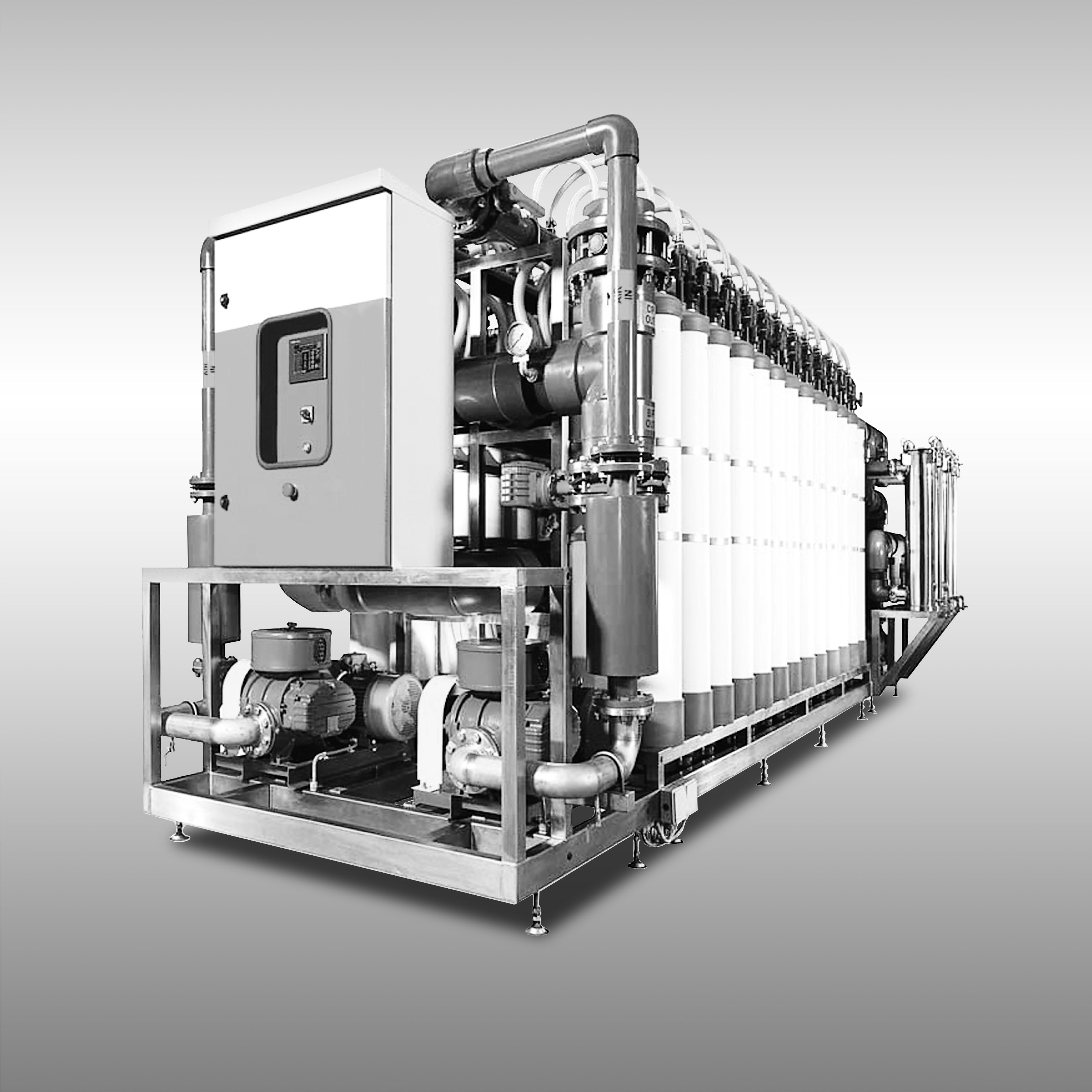

Patented design TurboClean®

Thanks to the patented TurboClean® design our modules for ultrafiltration, nanofiltration and reverse osmosis are the most resilient mechanically and are distinguished by higher productivity of filtration the most effective cleaning and simple installation.